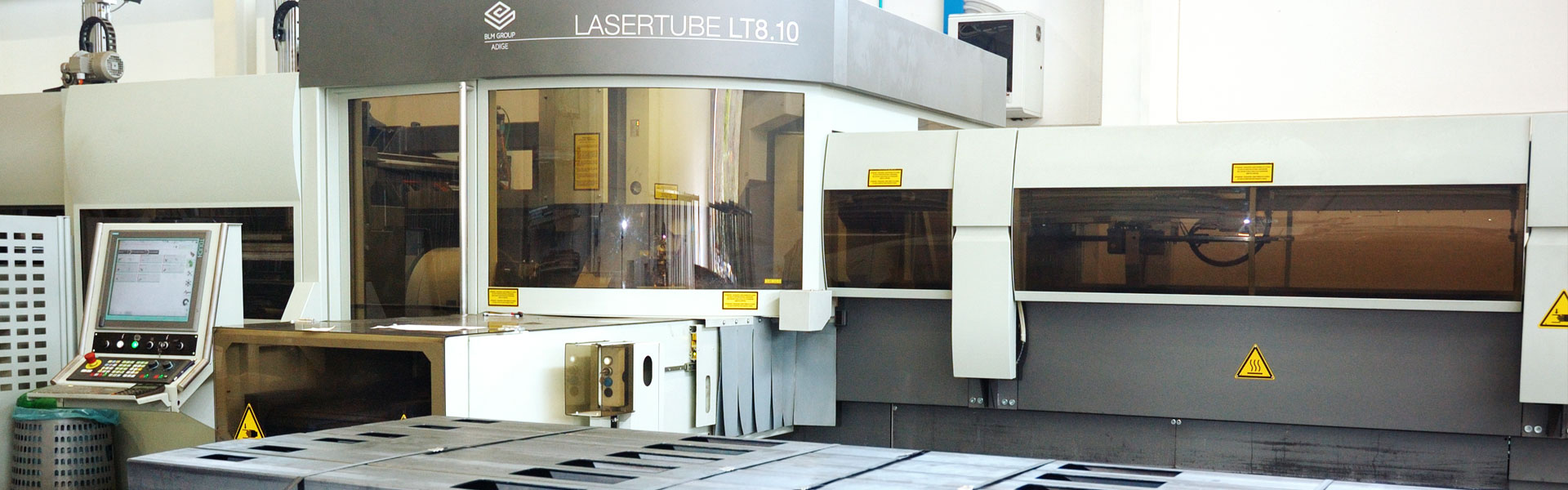

Productivity which can stand up to any comparison

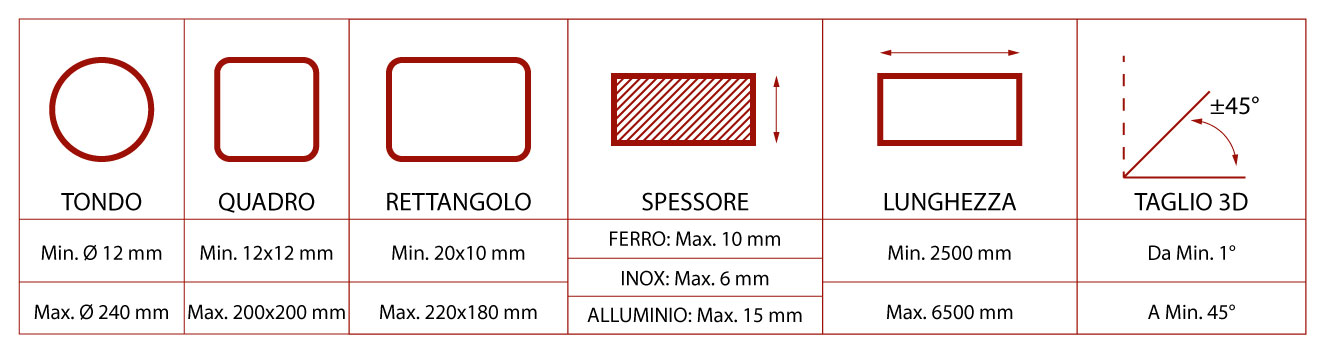

Our LT8 laser tube cutting center, can manage a range of workable tubes from 12 to 220 mm in diameter with up to 6500mm bar length, and a bar weight that can reach up to 40 Kg / m.

Our latest generation always expresses the highest quality and precision on any section, and as it is also equipped with an internal suction tube, it guarantees a slag-free cutting.

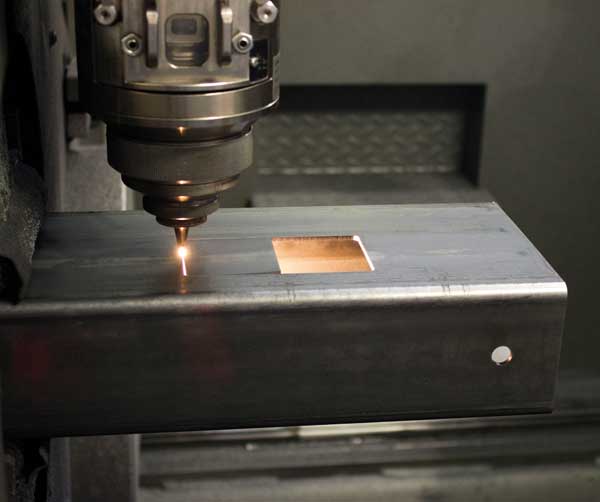

Equipped with a tilting cutting head, it allows 3D machining both on open profiles and on special sections.

Through an effective automatic loading device and a single discharging solution, the productivity of the LT8 is unmatched.

The automatic compaction of the pieces on the bar and the minimization of the end-of-bar waste, allow us to make the best use of the available material.

Through the automatic beam load with a capacity of 5,000 kg and one automatic single bar, we are able to manage all orders efficiently.

Fields of use and workable materials

The processes that can be carried out on tubes and profiles are many, among the most used, are punctures, slots, notches and inclined cuts. Amidst the most important and technological processes, we must remember the chamfering that is carried through with machines equipped with 3D laser cutting head, this processing is very important for metal carpentry jobs where full penetration welding is required.

Our Technical Department has the latest generation software which allows us to directly process the files provided by customers in different 3D formats with the following extensions: IGS, XT, STP, SAT,IFC. The direct use of the 3D files sent by the customer allows a significant reduction in the development time of the order and reduces any errors to zero due to the transformation of a drawing from 2D to three-dimensional format. As for the import of 2D files, files in DWG and DXF format can be imported.

In addition to the tubular laser cutting, the laser installed at the tube division of guazzi 2.0, can also work with considerable complexity on special profiles such as UNP - Angles - Plates, U-profiles, T-profiles, Omega, Special Profiles.

LASERTUBE LT8.10 CO2

CUTTING MATERIALS

Iron, galvanized iron, stainless steel, aluminum (some alloys).

SPECIAL OR OPEN PROFILES

Send us your request to

tecnico2.0@guazzi2-0.it