MANUAL AND ROBOTIC WELDING

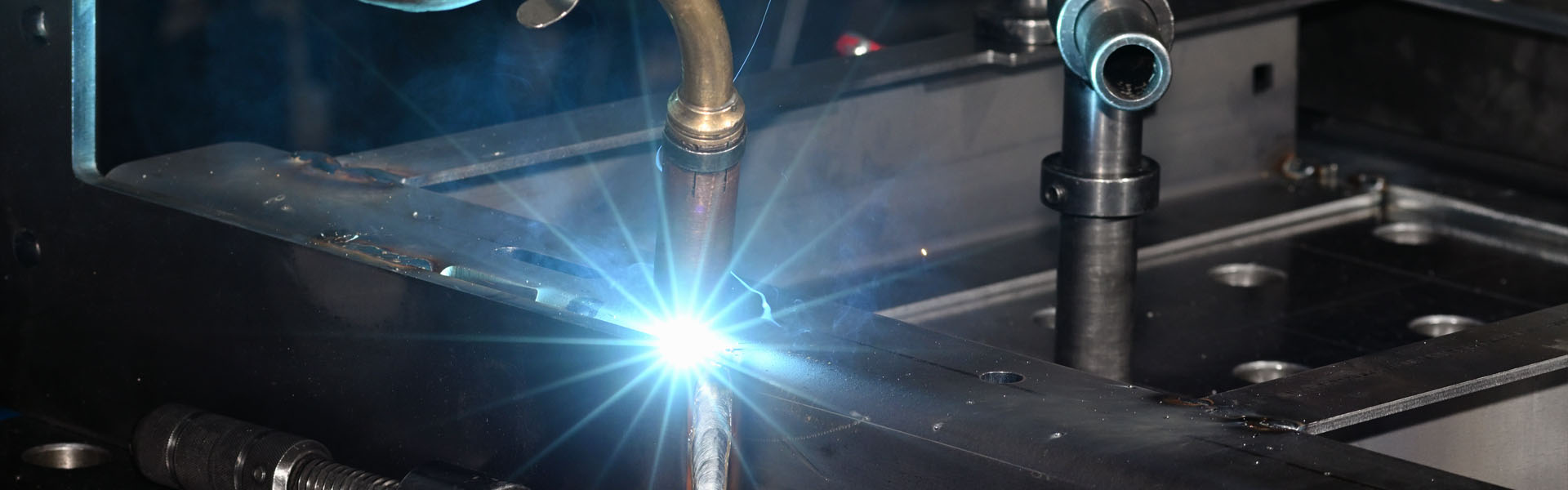

Guazzi 2.0 srl has a TIG and MIG welding department specialized in the processing of stainless steel and ferrous materials.

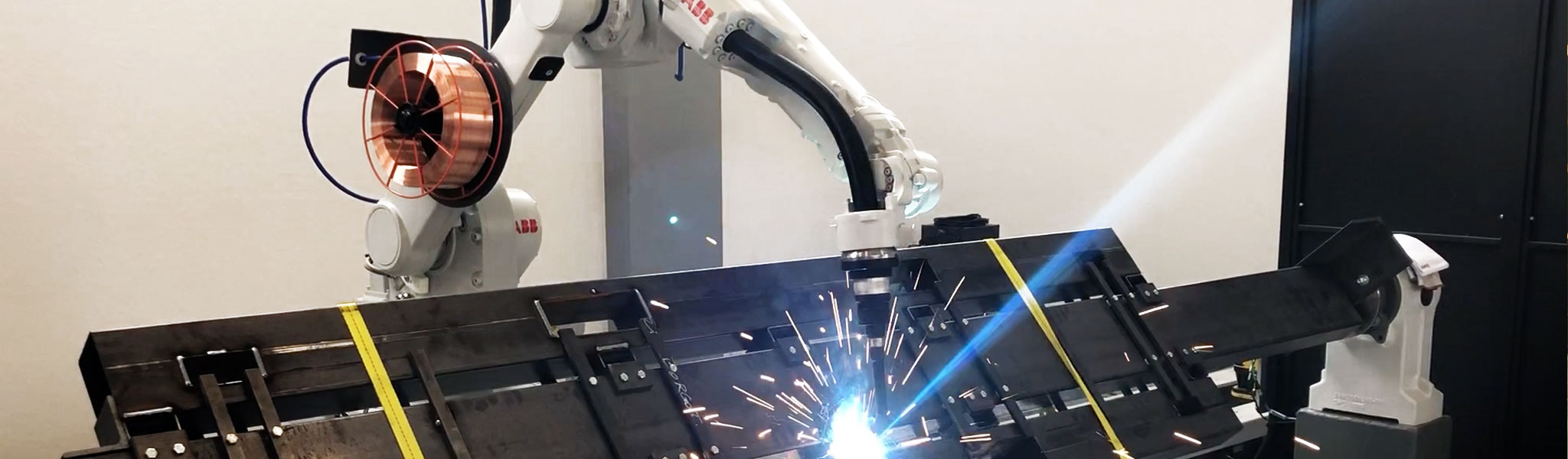

Although the traditional method of manual welding is still irreplaceable in some applications, robotic welding offers specific advantages, allowing to obtain an optimal quality of the certifiable weld bead.

The technology of our welding robot, combined with the experience gained by our operators, are the perfect combination for high-quality manufacturing.

Furthermore, the use of the welding robot allows us to finish the products rapidly, obtaining solutions without any inaccuracies or distortions, even on the most complex details.

The plant with which Guazzi 2.0 srl is equipped, consists of two rotating lathes and a six-axis anthropomorphic arm which slides on two tracks, cancelling downtime by working in masked time, therefore bringing the robot to its maximum productivity.

In our robotic welding station you can make parts with dimensions up to 4 meters by 1.5 meters in diameter.

Inside the welding department of the Guazzi 2.0 there are also two Manual welding stations equipped with the most advanced tools to maintain the same level of quality which distinguishes the robotic workstation.

WELDING

GENERAL INFORMATION

· Manual or Robotic with TIG and MIG welding.

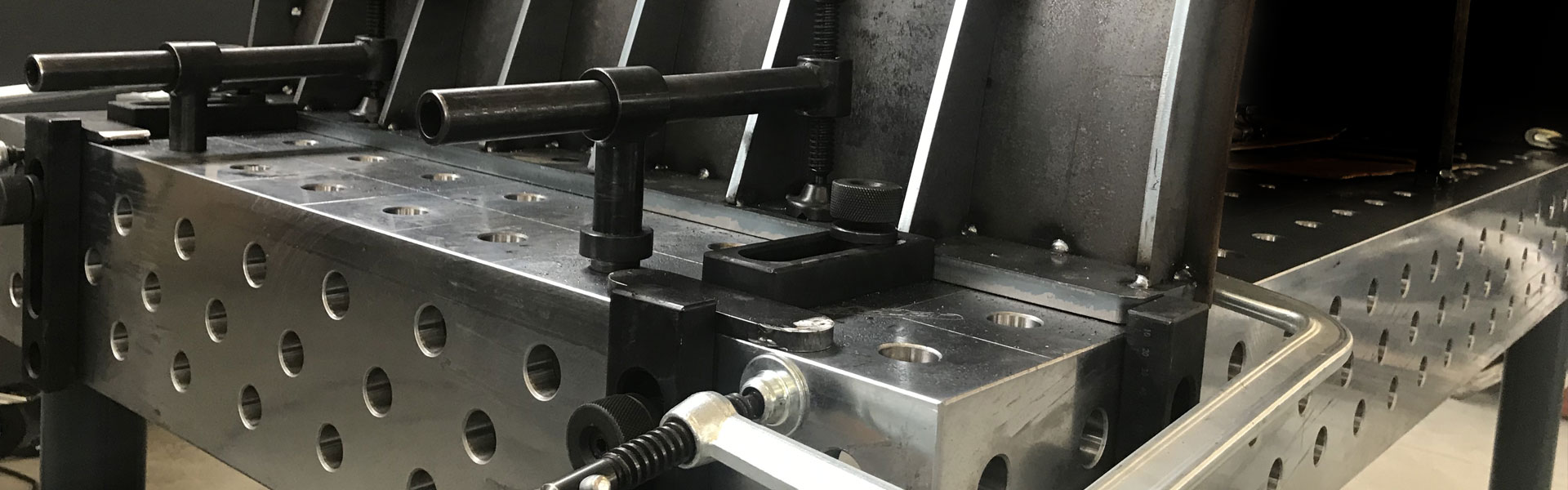

· Robotic welding work range: 4000 mm by 1500 mm on two rotating lathes.

· Perforated welding tables with hardened surface for working on heavy components.

WELDABLE MATERIAL

Iron, galvanized iron, stainless steel

CERTIFICABLE WELDINGS

All welds made in the robotic workstation can be certified on customer request.